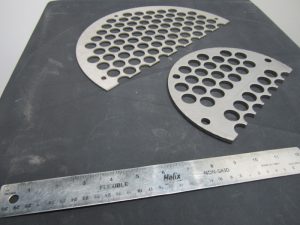

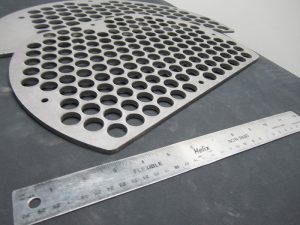

At Industrial Support Inc., we make it possible to take any custom design or component need and transform them into precision manufactured parts. In this project we were contracted by a NY-based water systems customer looking to manufacture a steel baffle for a water distribution project.

We applied metal forming, metal fabrication, and stamping procedures to complete this project. CNC machining equipment and a stamping press were used to manufacture the steel baffle, with tightest tolerances held to ±.030″. Final dimensions of the part were 0.25″ in thickness and 41.781″ in diameter.

We are a high quality, AS9100 (D) certified contract manufacturer able to assist in a wide variety of industries and applications. For more information about our custom fabrication or other capabilities, see the list below and contact us directly.

Steel Baffle Project Highlights

- Product Description

- Steel Baffle for water distribution

- Capabilities Applied/Processes

- Primary:

-

- Metal Forming and Fabrication

- Stamping

- Equipment Used to Manufacture Part

- CNC Machining

Stamp Press

- Overall Part Dimensions

- Length: .25”

Diameter: Up to 48”

- Tightest Tolerances

- ±.030”

- Material Used

- Steel

- In process testing/inspection performed

- Parts Inspection

Optical Comparators

Optical & Hard Gaging

- Industry for Use

- HVAC

- Standards Met

- Customer Specification

AS9100 (D)